Understanding the 75/25 Grade Designation of Bitumen & Its Manufacturing Process

Blown Bitumen 75/25, also known as Oxidized Bitumen or Blown Asphalt, is manufactured by injecting hot air into penetration-grade bitumen at elevated temperatures. This process alters the chemical structure, making the bitumen harder and more rubbery compared to its original form. The oxidation reduces its thermal sensitivity, resulting in a significantly higher softening point than regular bitumen. Consequently, the penetration index (PI) of Blown Bitumen 75/25 is considerably higher—typically ranging between 2 and 8—due to the gel-like consistency formed by asphalt accumulation during oxidation.

This grade of bitumen is semi-solid and derived from pure petroleum, featuring unique physical properties that make it highly suitable for various construction applications, especially where enhanced durability and resistance to heat are essential. The name “75/25” refers to the midpoint criteria for the softening point and penetration values that define this grade. Different grades are identified by two numbers indicating the midpoints of their softening point and penetration range, tailored to meet diverse industrial and construction needs.

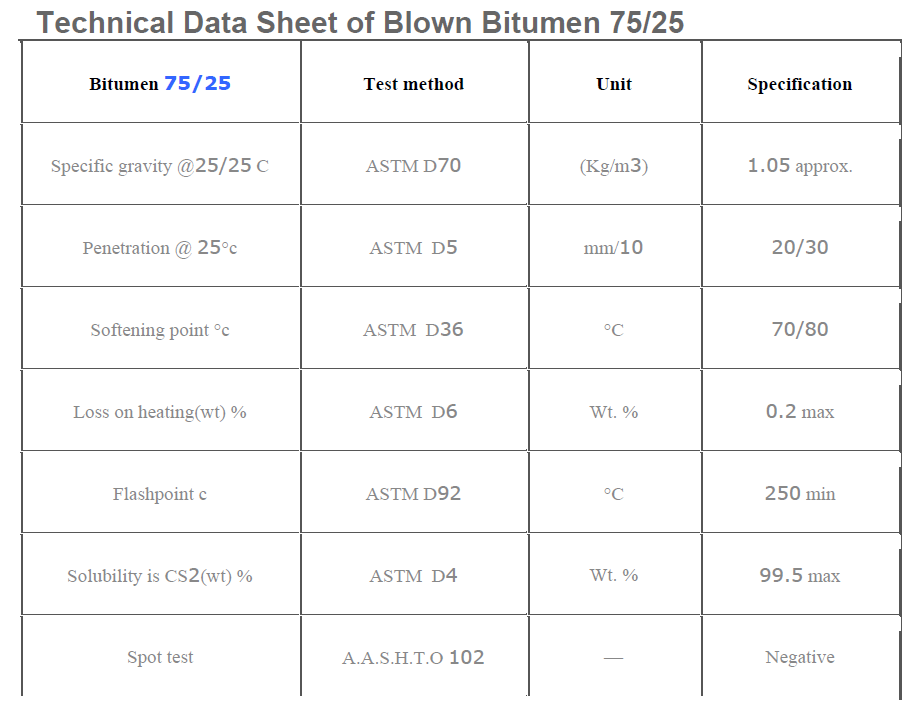

Blown Bitumen 75/25 is derived from petroleum bitumen by blowing very hot air into penetration grade bitumen 60/70. The numbers “75” and “25” correspond to the midpoint values of the material’s softening point and penetration, respectively. The softening point is measured using the Ring and Ball method, as specified by ASTM D36, while the penetration value—expressed in tenths of a millimeter—is determined according to IP49 or ASTM D5 standards.

Oxidized bitumen offers several key benefits:

- Fully water-resistant

- Highly flexible

- Exceptionally durable

- Chemically stable, enhancing overall performance

- Reliable for demanding applications

Thanks to these technical advantages, oxidized bitumen is widely favored in construction and industrial sectors where longevity and resilience are critical.

Applications and Performance of Oxidized or Blown Bitumen 75/25

Blown Bitumen 75/25 is a semi-solid, dark-colored material that softens and becomes gradually liquid when heated. This type of oxidized bitumen is produced by blowing air through soft bitumen at carefully controlled temperatures. This oxidation process enhances the bitumen’s rubber-like properties compared to standard penetration or hard grade bitumens, making it highly versatile for various industrial uses.

Blown Bitumen 75/25 is especially effective for sealing saw cuts and joints where minimal movement is expected, thanks to its wide temperature tolerance that prevents bleeding in hot conditions. Its robust physical characteristics make it suitable for a broad range of industrial applications, including pipe coating, roofing, waterproofing, flooring, adhesives, sound damping, carpet backing, and electrical insulation.

In addition, this hard bitumen grade is widely employed in construction and automotive industries. It serves as an anti-slip layer in piling, a key component in roofing felts, and a sealant in undercarriage protection. It is also used for electrical cable joint protection, joint filling, and soundproofing felts, among many other specialized applications where durability and stability are essential.

Key Performance Features of Blown Bitumen 75/25

Blown Bitumen 75/25 offers several notable technical benefits that make it a preferred choice for demanding industrial and construction applications. It is highly durable, ensuring long service life even under challenging conditions. Its flexibility allows it to adapt to different surfaces without cracking, while its excellent water resistance provides reliable protection against moisture ingress. In addition, its strong chemical stability enhances performance and maintains quality over time.

When compared to conventional paving grade bitumen, Blown Bitumen 75/25 demonstrates reduced temperature susceptibility, enabling it to perform well across a wider range of climatic conditions. It also retains a more solid consistency at ambient temperatures and has a significantly higher penetration index, making it more stable and less prone to deformation. These qualities collectively ensure that Blown Bitumen 75/25 remains a versatile and dependable material for various specialized applications.

Safe Handling and Storage Guidelines for Blown Bitumen 75/25

Heating packaged bitumen is a crucial step in preparing it for most end-use applications. Typically, the material is heated and melted in on-site boilers. However, precise control during this phase is essential—not only to maintain product quality but also to ensure health and safety compliance. The maximum safe handling temperature is 230°C, and exceeding this limit can damage the material and create hazards.

Since bitumen is a poor conductor of heat, careful management of the heating process is vital. Before placing oxidized bitumen into the boiler, it should be broken into smaller pieces. This increases the exposed surface area, allowing heat to distribute more evenly and reducing the risk of localized overheating. Without this step, excessive heat applied to the base or sides of the boiler can cause thermal cracking, alter the material’s properties, and release low-flash vapors, significantly increasing fire risk.

It is strongly advised never to leave melted bitumen in the boiler and then attempt to reheat it from cold. Poor convection in cooled bitumen can lead to uneven heat transfer, localized overheating, and even the formation of pressurized pockets of low-flash vapors.

Special attention should be given to the positioning of temperature monitoring and control devices. Due to bitumen’s low thermal conductivity, readings taken away from the heat source can be misleading—sometimes differing by several hundred degrees from the actual temperature near the heating elements. This discrepancy can result in unsafe conditions and product degradation.

By following these guidelines, both the performance and safety of Blown Bitumen 75/25 can be preserved, ensuring it meets the highest standards for industrial and construction applications.

Safety Precautions for Handling Blown Bitumen 75/25

When working with Blown Bitumen 75/25, always use protective masks, gloves, and goggles. Clean tools and equipment with kerosene or gasoline. Avoid overheating during the heating process to prevent hazards. For complete safety guidelines, consult the relevant Material Safety Data Sheet (MSDS).

Reliable Oxidized Bitumen 75/25 Supply for Global Industries

Edison Oil Company specializes in providing premium-quality Oxidized (Blown) Bitumen 75/25 to industries worldwide. With a robust supply network, stringent quality controls, and a commitment to timely delivery, we ensure that every batch meets exact technical specifications. Whether your requirement is for large-scale infrastructure projects or specialized industrial applications, we deliver tailored solutions to match your operational needs.

Serving sectors such as roofing, waterproofing, road construction, pipe coating, and industrial manufacturing, we are trusted for our product consistency, technical reliability, and competitive pricing. Our expertise in global logistics, combined with responsive customer support, makes us the preferred partner for businesses seeking dependable oxidized bitumen supply.

Connect with us today to discuss your requirements and experience a smooth, efficient supply process designed to keep your projects running on time and to the highest standards.

Uses of Blown Bitument 75/25